GB/T3287-2011 NB/T47008-2017 16Mn Material DN15 PN63 Union

16Mn Steel: Properties, Standards, Applications and Union Fittings

16Mn is a type of **low-alloy high-strength structural steel**. Its core feature is that it enhances strength by adding manganese, while maintaining excellent plasticity and weldability.

## I. Core Material Properties of 16Mn

1. **Chemical Composition**: The main component is iron (Fe), with manganese (Mn) as the key alloying element, accounting for approximately 1.2%-1.6%. Additionally, it contains a small amount of carbon (C ≤ 0.20%) and no or an extremely small amount of other alloying elements.

2. **Mechanical Properties**: The yield strength is about 345MPa (far exceeding the 235MPa of ordinary low-carbon steel), the tensile strength ranges from 470MPa to 630MPa, and it has good low-temperature impact toughness, allowing use in environments as low as -40℃.

3. **Implementation Standard**: The current domestic corresponding standard is **GB/T 1591-2018 "Low-Alloy High-Strength Structural Steels"**. In the old standard, the grade corresponding to 16Mn was Q345, and now it is uniformly classified into the Q345 series (e.g., Q345A/B/C/D/E).

The following table collates the main chemical composition of 16Mn (corresponding to the Q345 series) based on the standard GB/T 1591-2018 "Low-Alloy High-Strength Structural Steels", clearly indicating the content range and function of each element.

| Element Symbol | Element Name | Mass Fraction (%) | Notes (Function / Description) |

|---|---|---|---|

| C | Carbon | ≤ 0.20 | Determines the strength of the steel; excessive content reduces weldability and toughness. |

| Mn | Manganese | 1.20–1.60 | Core alloying element; enhances strength and low-temperature toughness, and improves weldability. |

| Si | Silicon | ≤ 0.55 | Deoxidizer; assists in enhancing strength; excessive content easily causes steel brittleness. |

| P | Phosphorus | ≤ 0.035 (Grade A/B); ≤ 0.030 (Grade C); ≤ 0.025 (Grade D/E) | Harmful impurity; easily causes "cold brittleness" of steel; stricter limits apply to higher quality grades. |

| S | Sulfur | ≤ 0.035 (Grade A/B); ≤ 0.030 (Grade C); ≤ 0.025 (Grade D/E) | Harmful impurity; easily causes "hot brittleness" of steel and affects welding and processing performance. |

| V/Nb/Ti | Vanadium/Niobium/Titanium | Single element ≤ 0.15; total ≤ 0.22 | Optional micro-alloying elements (often contained in Grade D/E); refine grain size and further enhance strength. |

## II. Main Applications of 16Mn

Its applications center on the characteristics of "high strength + easy processing" and cover multiple industrial fields:

- **Engineering Structures**: Used in building steel structures (e.g., workshops, bridges, venues) and construction machinery (e.g., crane booms, excavator arms), which can reduce steel consumption and lower the self-weight of structures.

## II. Main Applications of 16Mn

Its applications center on the characteristics of "high strength + easy processing" and cover multiple industrial fields:

- **Engineering Structures**: Used in building steel structures (e.g., workshops, bridges, venues) and construction machinery (e.g., crane booms, excavator arms), which can reduce steel consumption and lower the self-weight of structures.

- **Mechanical Manufacturing**: Used to manufacture parts that bear medium loads, such as machine tool spindles, gears, connecting rods, as well as the shells and heads of pressure vessels and boilers.

- **Pipeline Field**: Used in medium and high-pressure steel pipes for transporting oil, natural gas, and water, especially large-diameter straight-seam welded pipes or spiral welded pipes, which can meet the pressure requirements of long-distance transportation.

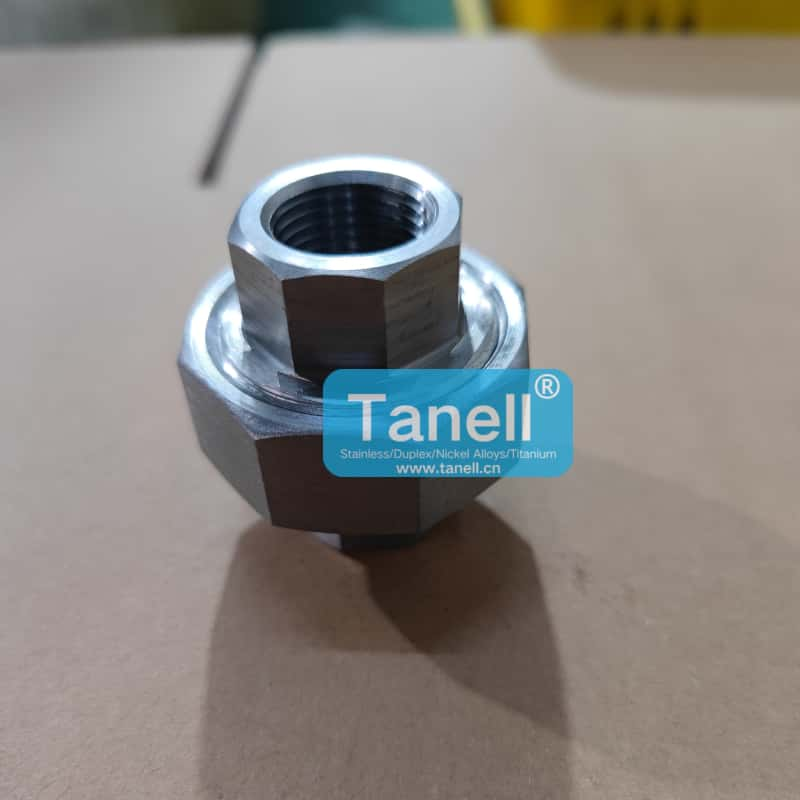

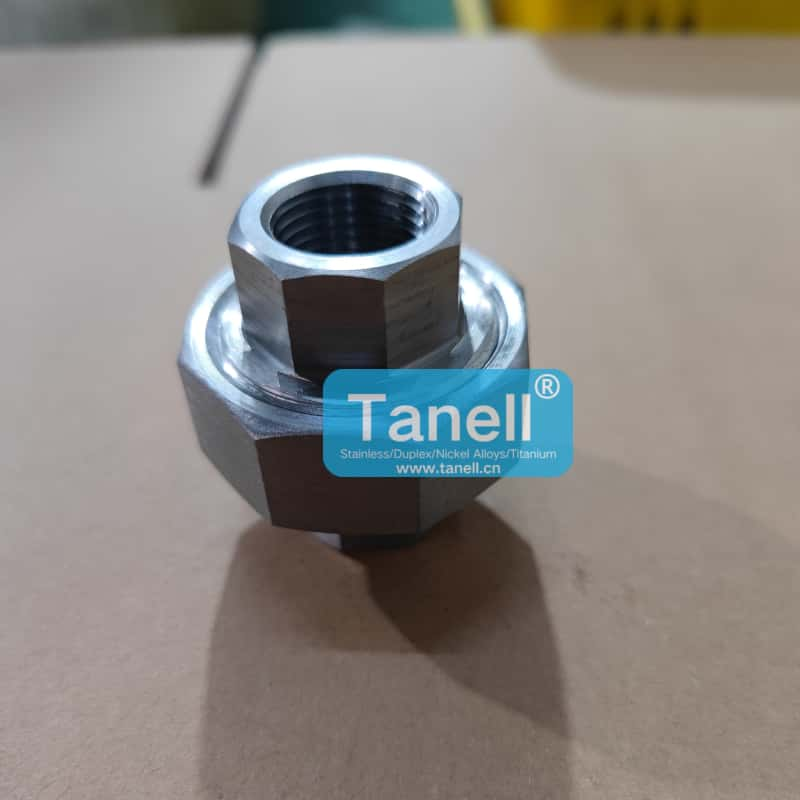

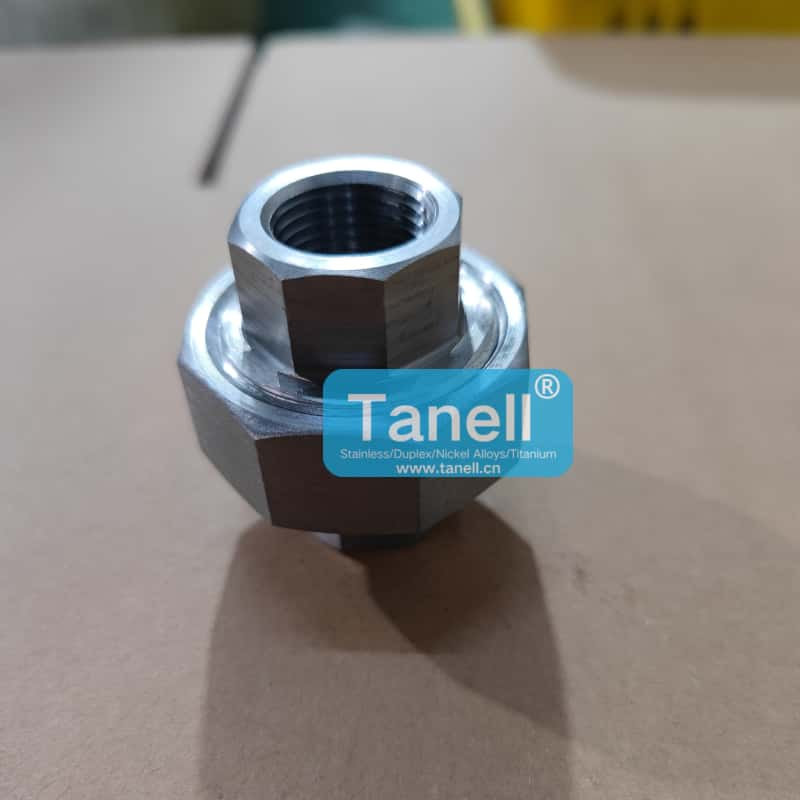

A union fitting is a detachable connecting component in a pipeline system. Its core purpose is to enable quick disassembly, maintenance, or replacement of the pipeline without damaging the overall structure of the pipeline.

### I. Core Purposes of Union Fittings

- **Facilitating Maintenance and Replacement**: When equipment such as valves, water meters, and water pumps in the middle of the pipeline is damaged, there is no need to cut the pipeline; only the union fitting needs to be unscrewed to disassemble the faulty component, which greatly shortens the maintenance time.

- **Simplifying Installation and Adjustment**: During pipeline construction, if there is a slight deviation between two sections of the pipeline, the adjustability of the union fitting can help achieve precise alignment, avoiding installation difficulties caused by dimensional errors.

- **Facilitating System Inspection and Cleaning**: Some fluid pipelines (e.g., drinking water pipes, industrial material pipes) require regular cleaning or internal condition inspection. Union fittings can be used as temporary openings to facilitate resealing after operation.

- **Protecting Vulnerable Components**: For vulnerable parts that require frequent maintenance (e.g., filter elements), union fittings can reduce repeated disassembly of the pipeline itself and extend the overall service life of the pipeline.

- **Mechanical Manufacturing**: Used to manufacture parts that bear medium loads, such as machine tool spindles, gears, connecting rods, as well as the shells and heads of pressure vessels and boilers.

- **Pipeline Field**: Used in medium and high-pressure steel pipes for transporting oil, natural gas, and water, especially large-diameter straight-seam welded pipes or spiral welded pipes, which can meet the pressure requirements of long-distance transportation.

A union fitting is a detachable connecting component in a pipeline system. Its core purpose is to enable quick disassembly, maintenance, or replacement of the pipeline without damaging the overall structure of the pipeline.

### I. Core Purposes of Union Fittings

- **Facilitating Maintenance and Replacement**: When equipment such as valves, water meters, and water pumps in the middle of the pipeline is damaged, there is no need to cut the pipeline; only the union fitting needs to be unscrewed to disassemble the faulty component, which greatly shortens the maintenance time.

- **Simplifying Installation and Adjustment**: During pipeline construction, if there is a slight deviation between two sections of the pipeline, the adjustability of the union fitting can help achieve precise alignment, avoiding installation difficulties caused by dimensional errors.

- **Facilitating System Inspection and Cleaning**: Some fluid pipelines (e.g., drinking water pipes, industrial material pipes) require regular cleaning or internal condition inspection. Union fittings can be used as temporary openings to facilitate resealing after operation.

- **Protecting Vulnerable Components**: For vulnerable parts that require frequent maintenance (e.g., filter elements), union fittings can reduce repeated disassembly of the pipeline itself and extend the overall service life of the pipeline. ### II. Common Application Scenarios

- **Civil Field**: Tap water pipelines in households or residential communities (connecting water meters, water heaters, water purifiers) and gas pipelines (connecting gas meters, gas stoves).

- **Industrial Field**: Chemical fluid transportation pipelines, heating/refrigeration system pipelines, and water/gas inlet and outlet pipelines of mechanical equipment.

Zhejiang tanell Pipe Industry Technology Co., Ltd. specializes in the production of various high-pressure forged pipe fittings.

### II. Common Application Scenarios

- **Civil Field**: Tap water pipelines in households or residential communities (connecting water meters, water heaters, water purifiers) and gas pipelines (connecting gas meters, gas stoves).

- **Industrial Field**: Chemical fluid transportation pipelines, heating/refrigeration system pipelines, and water/gas inlet and outlet pipelines of mechanical equipment.

Zhejiang tanell Pipe Industry Technology Co., Ltd. specializes in the production of various high-pressure forged pipe fittings.